How Do On-Metal RFID Tags Work on Metal Surfaces?

Table of Contents

On-Metal RFID Tags: How They Work & Why Industrial Buyers Need Them

Why Standard RFID Tags Struggle on Metal Surfaces

Standard RFID tags, while cost-effective and widely used, are not designed to perform reliably on metal surfaces. You’re not alone if you’re trying to tag metal equipment, tools, or containers with regular RFID tags and experiencing read failures or erratic performance. Here’s why this happens:

1. Signal Reflection and Interference

Radio waves emitted by an RFID reader bounce off metal surfaces, leading to multi-path interference. This means the signal scatters unpredictably, confusing the RFID reader and resulting in:

- Missed reads

- Duplicate tag reads

- Reduced read accuracy

Example: In a warehouse, scanning a metal rack of products may result in inconsistent reads due to signal reflections.

2. Antenna Detuning

RFID tags contain antennas designed to resonate at specific frequencies (like UHF or HF). When a tag is placed on metal, the conductive surface alters the electromagnetic field, detuning the antenna and rendering the tag ineffective.

This leads to:

- Complete signal loss

- Poor tag-to-reader communication

- Severely reduced read range

Analogy: It’s like using a radio tuned to the wrong frequency — the connection doesn’t work.

3. Power Drain in Passive Tags

Passive RFID tags rely on the energy from the RFID reader’s signal to power the chip and send back data. But metal surfaces absorb or deflect this energy, leaving the tag with insufficient power to function.

This results in:

- Tags not activating

- Partial data transfer

- Reduced tag lifespan in mission-critical applications

Impact: In industrial environments with large metal machinery or metallic packaging, passive tags often fail unless properly shielded.

4. Inconsistent Read Zones

When using standard RFID tags near or on metal:

- The read zone becomes unpredictable

- Tags work in some positions but not others

- System reliability drops, frustrating operators and delaying workflows

Bottom Line: Standard metal tags compromise operational accuracy and ROI if you rely on RFID for real-time tracking and inventory visibility.

What Are On-Metal RFID Tags?

On-metal RFID tags (also called anti-metal RFID tags or metal-mount RFID tags) are specially designed RFID transponders engineered to work effectively on or near metal surfaces — something traditional RFID tags can’t reliably do.

These tags are not just slightly modified versions of regular RFID tags — they are purpose-built using advanced materials and design strategies to overcome metal-induced interference.

How They’re Built

To function on metal, these tags incorporate:

Insulating layers: Separate the RFID antenna and chip from the metal surface to prevent detuning.

Ferrite backing: A magnetic layer redirecting electromagnetic fields, allowing clean signal transmission.

Optimized antennas: Explicitly engineered for near-field environments with conductive surfaces.

Durable housings: Materials like ABS, epoxy, or metal casings protect the tag from industrial abuse, such as vibration, dust, oil, or moisture.

These components work together to ensure the tag transmits data reliably even when mounted directly on metallic tools, machinery, vehicles, or containers.

Design Variants

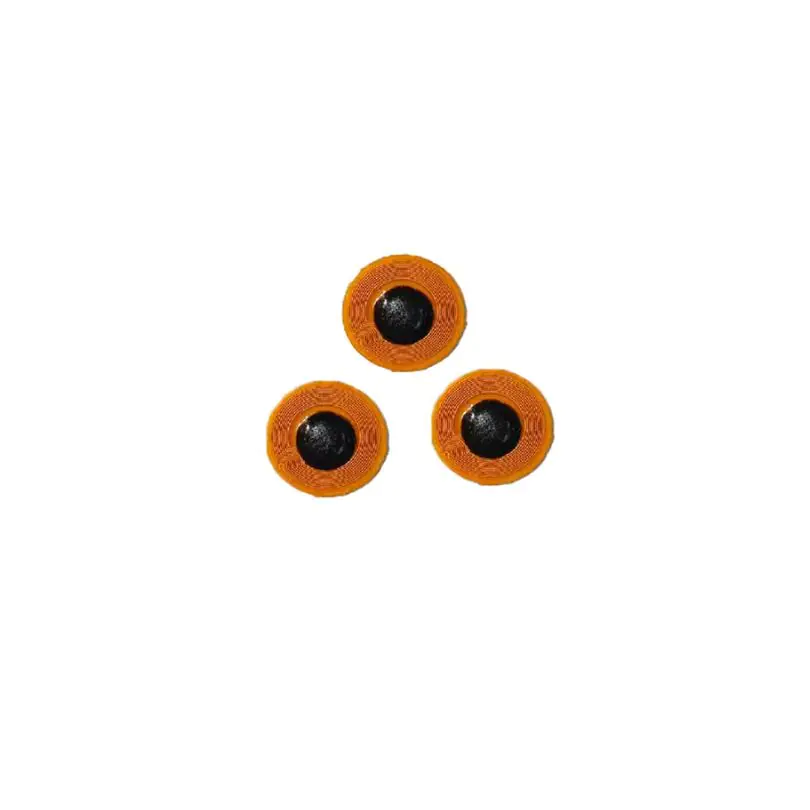

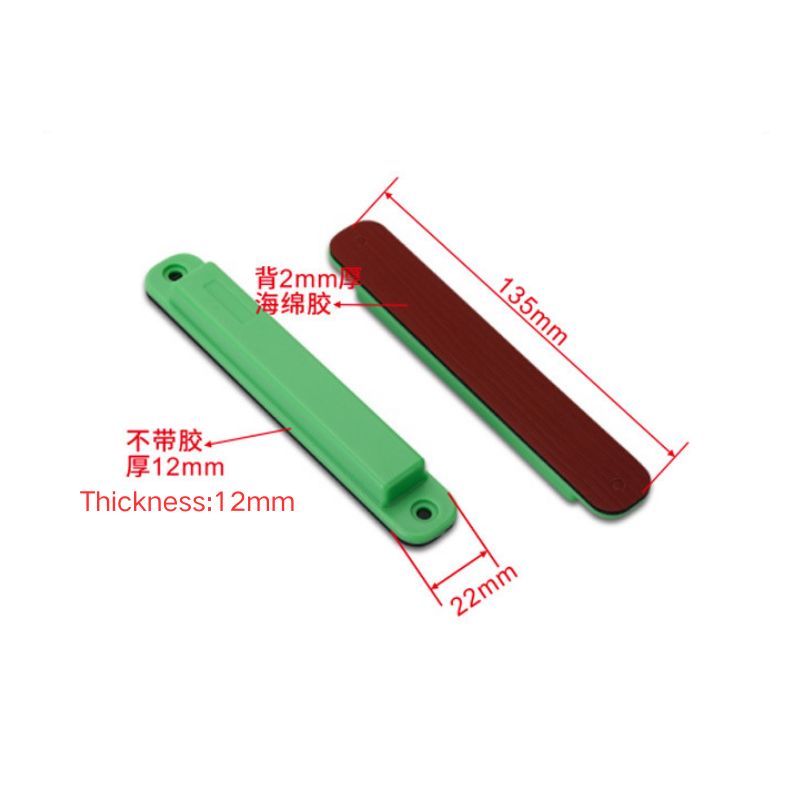

On-metal RFID tags come in a variety of shapes and sizes to fit your operational needs, including:

- Flat tags for surface mounting on metal shelves or containers.

- Curved or flexible tags for pipes and cylindrical equipment.

- Rugged coin tags for embedding in tools or metallic assets.

- Labels with foam spacing for cost-effective, one-time-use applications.

View our full On-Metal RFID Tag product line

How On-Metal RFID Tags Work: Engineering That Overcomes Interference

RFID technology relies on smooth communication between a reader and a tag via radio frequency waves. However, this communication gets disrupted when metal is introduced into the environment, unless the tag is specifically engineered to function in such conditions.

That’s exactly what on-metal RFID tags are built for.

The Core Challenge: Metal Disrupts Electromagnetic Fields

In standard RFID systems, the antenna inside the tag resonates at a specific frequency (typically UHF or HF). When placed on metal:

- The antenna’s resonant frequency changes (detuning)

- The radio signal is absorbed or reflected unpredictably

- Communication between the reader and the tag becomes unstable or completely interrupted

On-metal RFID tags use a multi-layered design to overcome these challenges.

Key Takeaways for Standard RFID Tag and On-Metal RFID Tag

| Feature | Standard RFID Tag | On-Metal RFID Tag |

| Works on Metal Surfaces | ❌ Fails or weak signal | ✅ Engineered for metal |

| Read Range Near Metal | ⛔ Severely reduced | ✅ Up to 10 meters (UHF) |

| Resistance to Interference | ❌ Unreliable | ✅ Ferrite-backed shielding |

| Durability in Harsh Envs | ⚠️ Limited | ✅ IP67+ certified materials |

Need Help Choosing the Right Tag?

JIA RFID’s engineering team provides free consultations and custom solutions for industrial clients. We can recommend the perfect product if you’re tracking heavy machinery, containers, or equipment in harsh environments.

Industrial Applications of On-Metal RFID Tags

On-metal RFID tags are a game-changer for industries that rely on metal tools, parts, structures, and equipment. Unlike traditional tags, these are built for rugged, metal-heavy environments where precision, durability, and real-time data are essential.

Below are key industries and real-world applications where JIA RFID’s factory-direct on-metal tags improve operations, cut costs, and enhance traceability.

1. Manufacturing & Industrial Equipment

Use Cases:

- Tracking tools, dies, and fixtures on the production floor

- Monitoring work-in-progress (WIP) items moving between stations

- Identifying metal machinery for maintenance scheduling

Benefit:

Ensures tool accountability, reduces production delays, and supports preventive maintenance through real-time visibility.

Related Product: RFID Disc & Coin Tags →

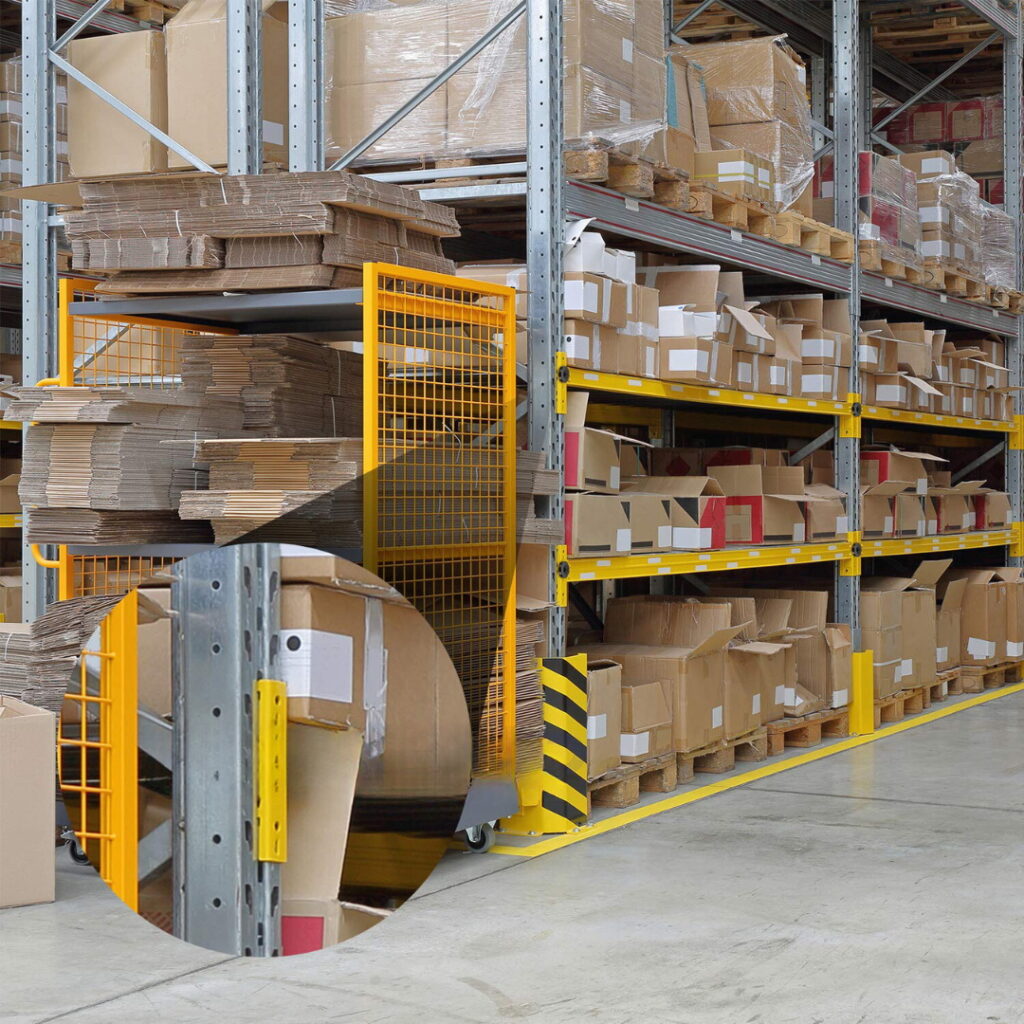

2. Logistics & Warehousing

Use Cases:

- Managing metal shipping containers, pallets, and crates.

- Tracking returnable transport items (RTIs).

- Automating gate-in/gate-out scanning with handheld readers.

Benefit:

Eliminates manual scanning, reduces asset loss, and speeds up inventory audits with bulk-read capability.

Related Product: Handheld RFID Readers →

3. Oil & Gas

Use Cases:

- Identifying and tracking metal pipes, valves, and flanges

- Monitoring drilling equipment on offshore rigs

- Maintaining inspection and certification records

Benefit:

Improves safety compliance and asset traceability in corrosive, high-temperature environments where barcode labels fail.

Why RFID Wins: On-metal tags resist water, pressure, and chemicals that commonly degrade standard tracking labels.

4. Aerospace & Aviation

Use Cases:

- Tracking aircraft parts and structural components

- Managing tools and calibration equipment in hangars

- Automating MRO (Maintenance, Repair, Overhaul) documentation

Benefit:

Enhances traceability of mission-critical components while reducing paperwork and human error in safety-sensitive environments.

Bonus: Metal-safe RFID tags meet aviation-grade requirements and withstand vibrations and pressure fluctuations.

5. Construction & Infrastructure

Use Cases:

Tagging steel beams, scaffolding, and metallic fixtures

Tracking high-value tools and mobile equipment

Recording inspections on building components

Benefit:

Reduces equipment loss, prevents tool hoarding, and ensures compliance with site safety standards.

6. IT Asset Management & Data Centers

Use Cases:

Labeling and inventorying metal servers and network devices

Securing backup drives, racks, and mobile carts

Supporting audits with handheld RFID scanning

Benefit:

Speeds up compliance reporting, minimizes manual errors, and supports asset traceability in high-density server rooms.

Enhance with: RFID Readers for Data Centers →

Ready to Tag Metal Assets at Scale?

JIA RFID offers bulk pricing, sample kits, and custom solutions to fit your application, no matter how harsh the conditions.

Why Buy From JIA RFID?

As a factory-direct manufacturer, JIA RFID offers:

- Custom design support for unique metal surfaces

- Competitive bulk pricing with fast lead times

- Global shipping for B2B clients

- In-house engineering for specialized environments

Explore more RFID tag types:

🔹 RFID Disc & Coin Tags

🔹 Handheld RFID Readers

Product Highlight: On-Metal RFID Tag Features

- Frequency: UHF (860–960 MHz) or HF options

- Read Range: Up to 10 meters (UHF)

- IP Rating: IP67+ for industrial environments

- Mounting Options: Adhesive, screw, rivet

FAQs

Do RFID tags really work on metal?

Yes. On-metal RFID tags are designed to handle metal interference, making them ideal for tagging metal tools, machinery, and equipment.

How much do on-metal RFID tags cost?

Prices vary by type and volume. For passive versions, bulk pricing starts as low as $0.50 per tag. Get custom quotes for your industry.

Are your RFID tags waterproof and heat-resistant?

Yes, many of our on-metal RFID tags meet IP67+ standards and are designed for use in harsh industrial environments.

Can I test them before I buy?

Absolutely. We offer free samples for qualified projects. Contact us for evaluation support.

Comments

Hot Products

How RFID Tag on Windscreen Improves Vehicle Access Control and Toll Systems

In today’s fast-paced world, vehicle identification needs to be quick, secure, and contactless. An RFID Tag on the Windscreen provides exactly that — a reliable way to manage toll collection, parking, and gated access without stopping vehicles.

The Benefits of RFID Linen Tags in Commercial Laundry

Managing laundry in hospitals, hotels, or large laundry services is a big job. Each day, thousands of sheets, towels, and uniforms are washed, sorted, and sent back out. But problems like lost linens, sorting mistakes, and manual counting can cost companies a lot of money. For example, mid-sized hotels can lose over $200,000 each year from missing linens.

That’s where RFID Linen Tags come in.

How to Use RFID Laundry Tags: The Complete Guide to Installation, Applications, and Benefits

In industries where linen and garment management is critical—such as hospitality, healthcare, fitness centers, and clothing rentals—RFID laundry tags have become an essential technology.

How RFID Tags for Pallet Streamline Tracking in Warehouses

In today’s fast-paced logistics and supply chain environments, traditional pallet tracking methods like barcodes and manual scanning are no longer sufficient. This is where RFID (Radio Frequency Identification) comes in.

Top 5 Types RFID Tag for Warehouse Automation

Warehouse operations are becoming more complex, and manual tracking methods can’t keep up. RFID tags for warehouse automation enable real-time data capture, faster inventory processing, and better traceability.

RFID Smart License Plates Help Hengshui to Track The E-Bikes

As urbanization accelerates and the green travel movement gains momentum, electric bicycles have become vital to daily commuting in Hengshui, Henan Province.

Tags

RELATED BLOGS

How RFID Tag on Windscreen Improves Vehicle Access Control and Toll Systems

In today’s fast-paced world, vehicle identification needs to be quick, secure, and contactless. An RFID Tag on the Windscreen provides exactly that — a reliable way to manage toll collection, parking, and gated access without stopping vehicles.

The Benefits of RFID Linen Tags in Commercial Laundry

Managing laundry in hospitals, hotels, or large laundry services is a big job. Each day, thousands of sheets, towels, and uniforms are washed, sorted, and sent back out. But problems like lost linens, sorting mistakes, and manual counting can cost companies a lot of money. For example, mid-sized hotels can lose over $200,000 each year from missing linens.

That’s where RFID Linen Tags come in.

How to Use RFID Laundry Tags: The Complete Guide to Installation, Applications, and Benefits

In industries where linen and garment management is critical—such as hospitality, healthcare, fitness centers, and clothing rentals—RFID laundry tags have become an essential technology.